“Back in the summer of 2019, the average time it took for the IT department to process an application was two weeks, this figure has now dropped to one and a half days”

Whether we are talking about apartments and offices or factories and warehouse complexes, where the most complex of engineering solutions are often found, high-quality ventilation is necessary not only for the well-being and overall mood of the staff but also for the safety of goods.

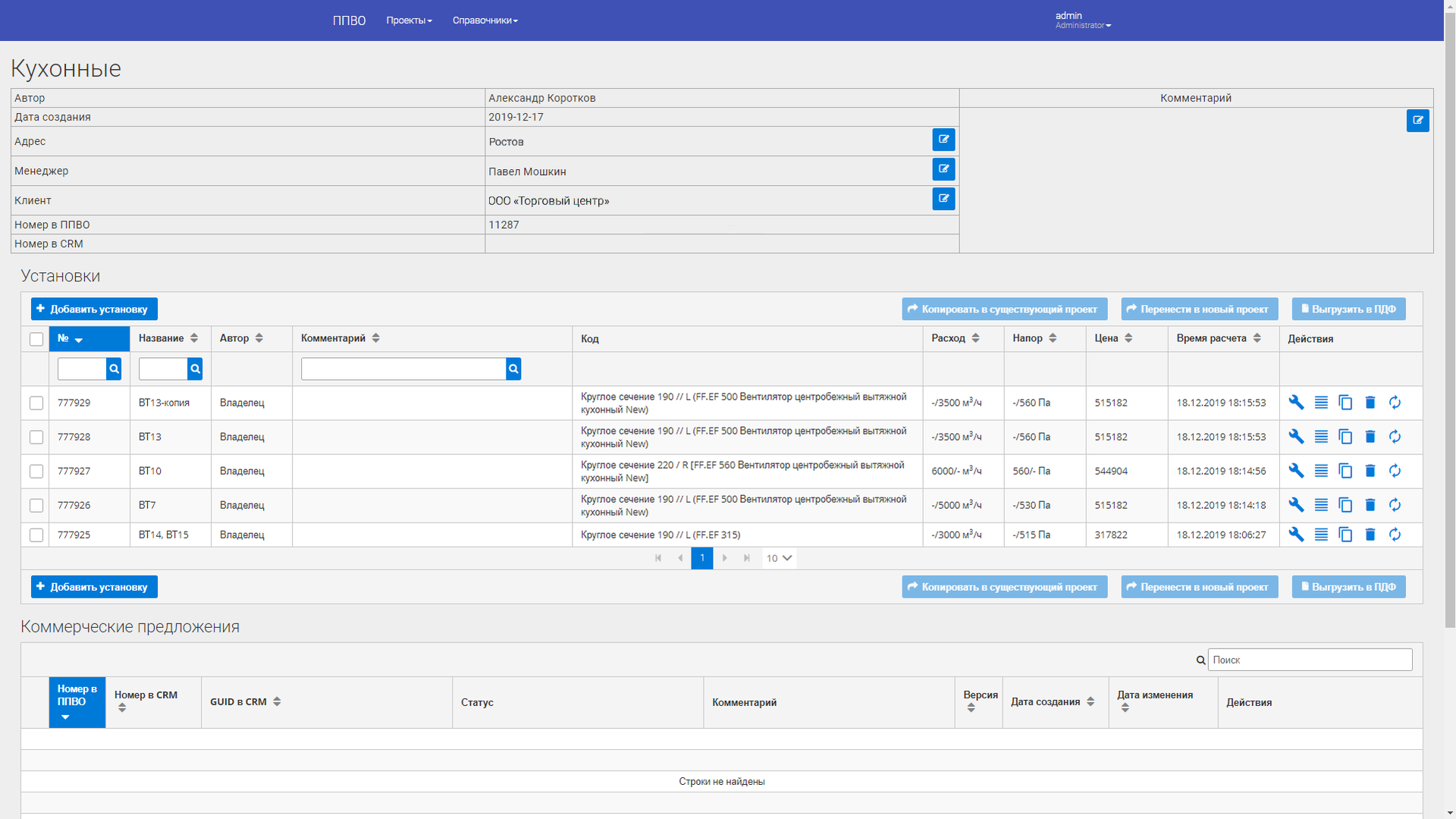

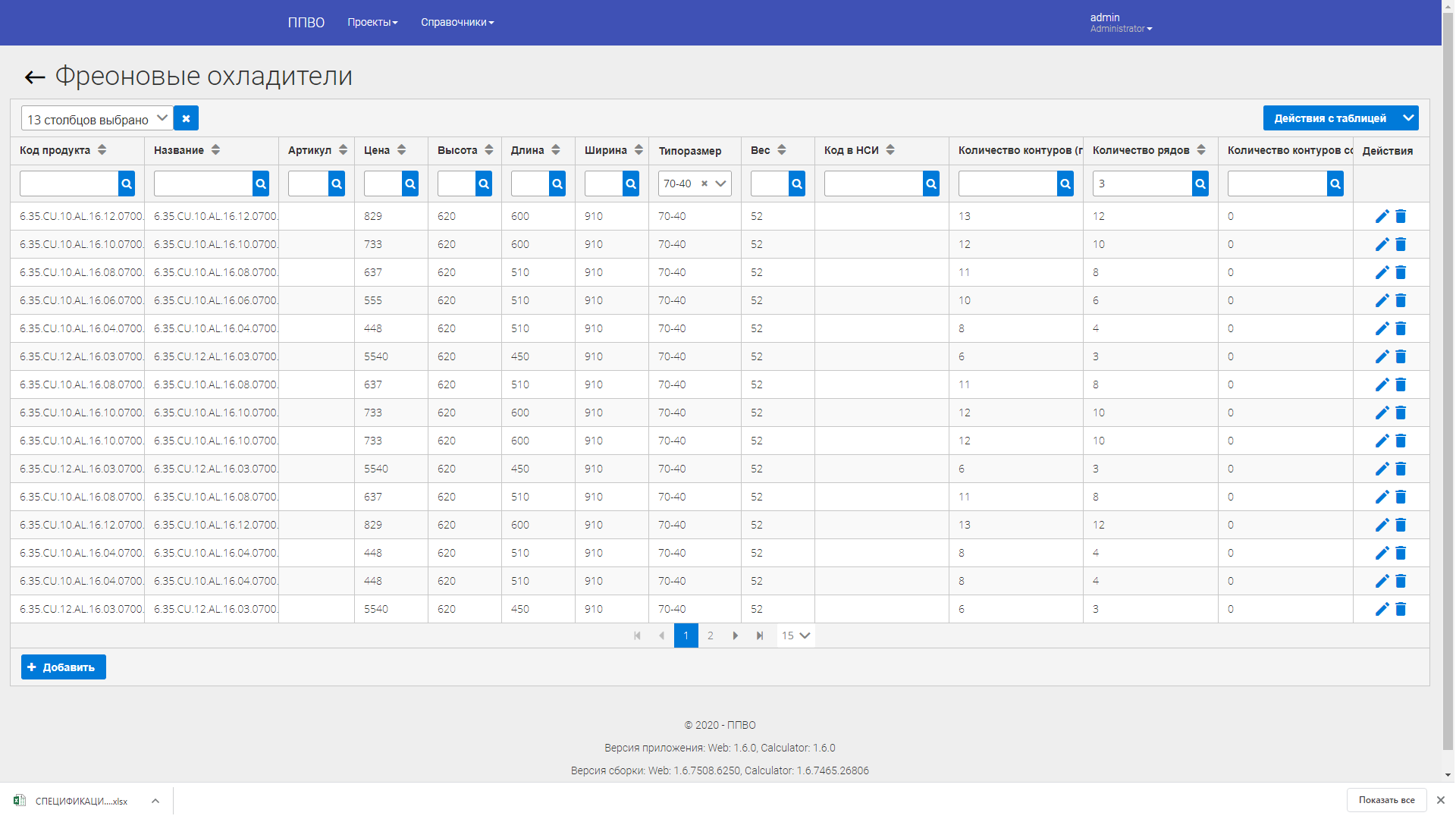

By order of the largest manufacturer and importer of climate equipment in Europe and the CIS, Rusklimat Holdings, a “Ventilation Equipment Selection Program” (VESP) was created for the design and sale of ventilation equipment.

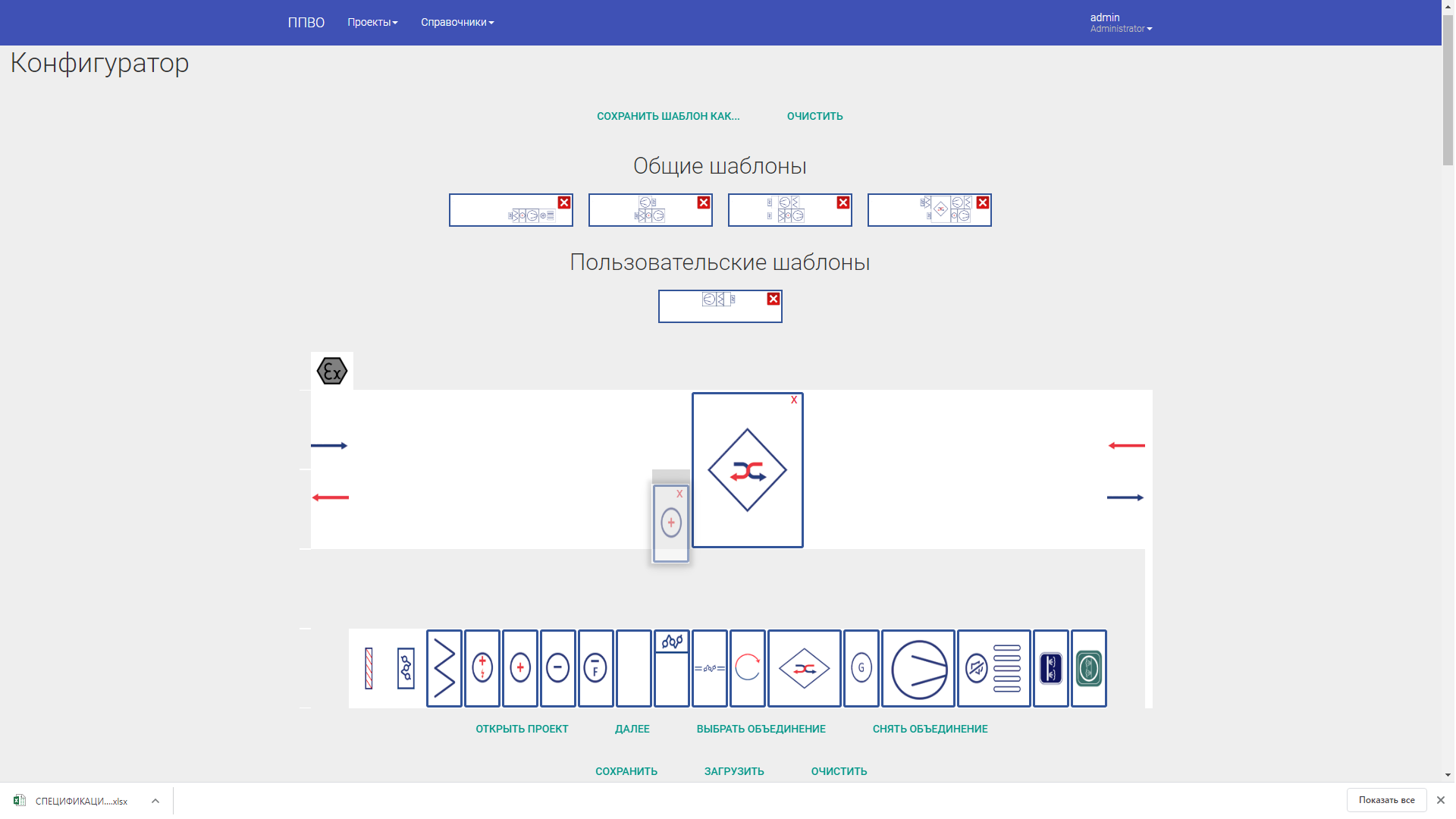

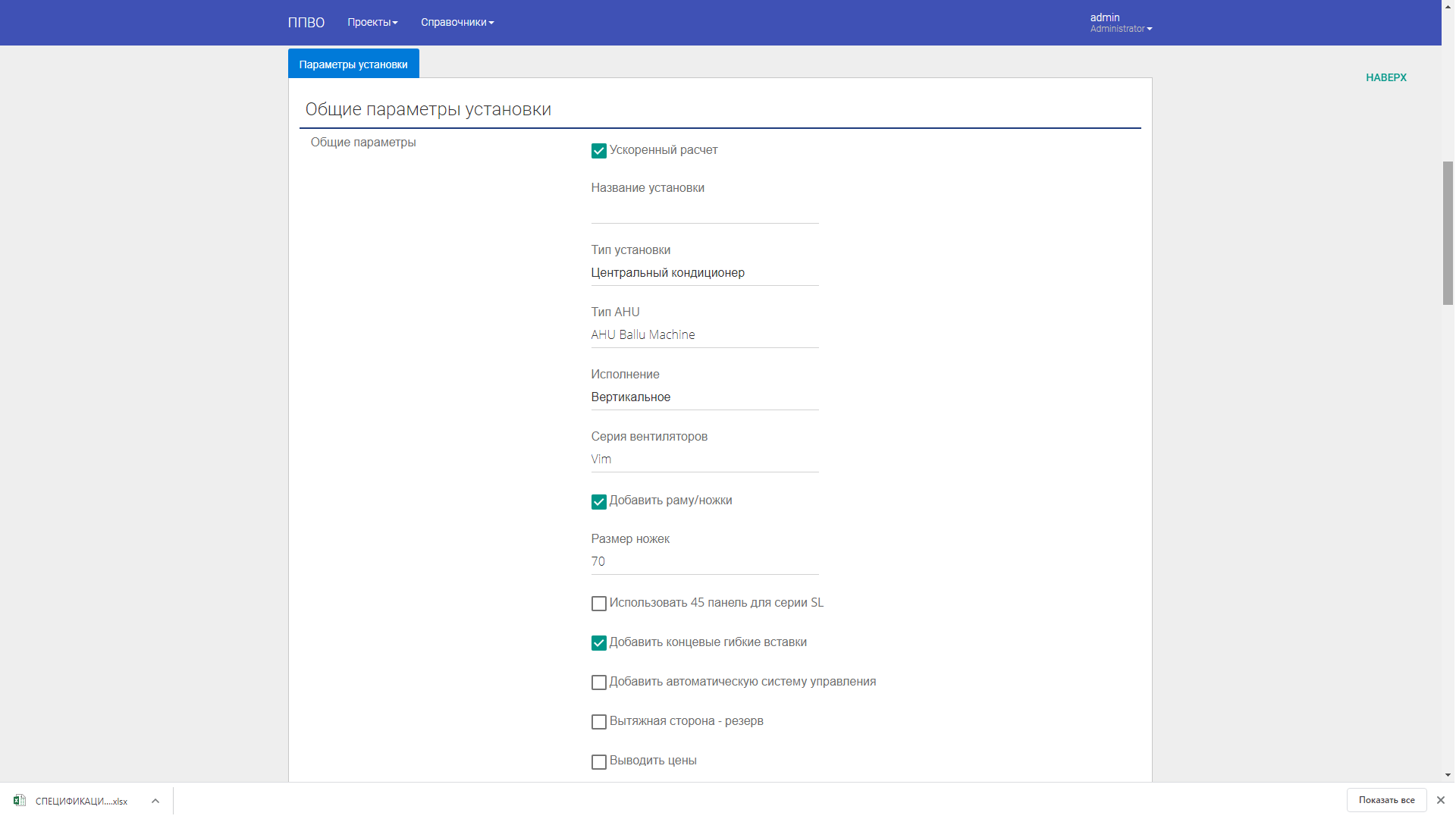

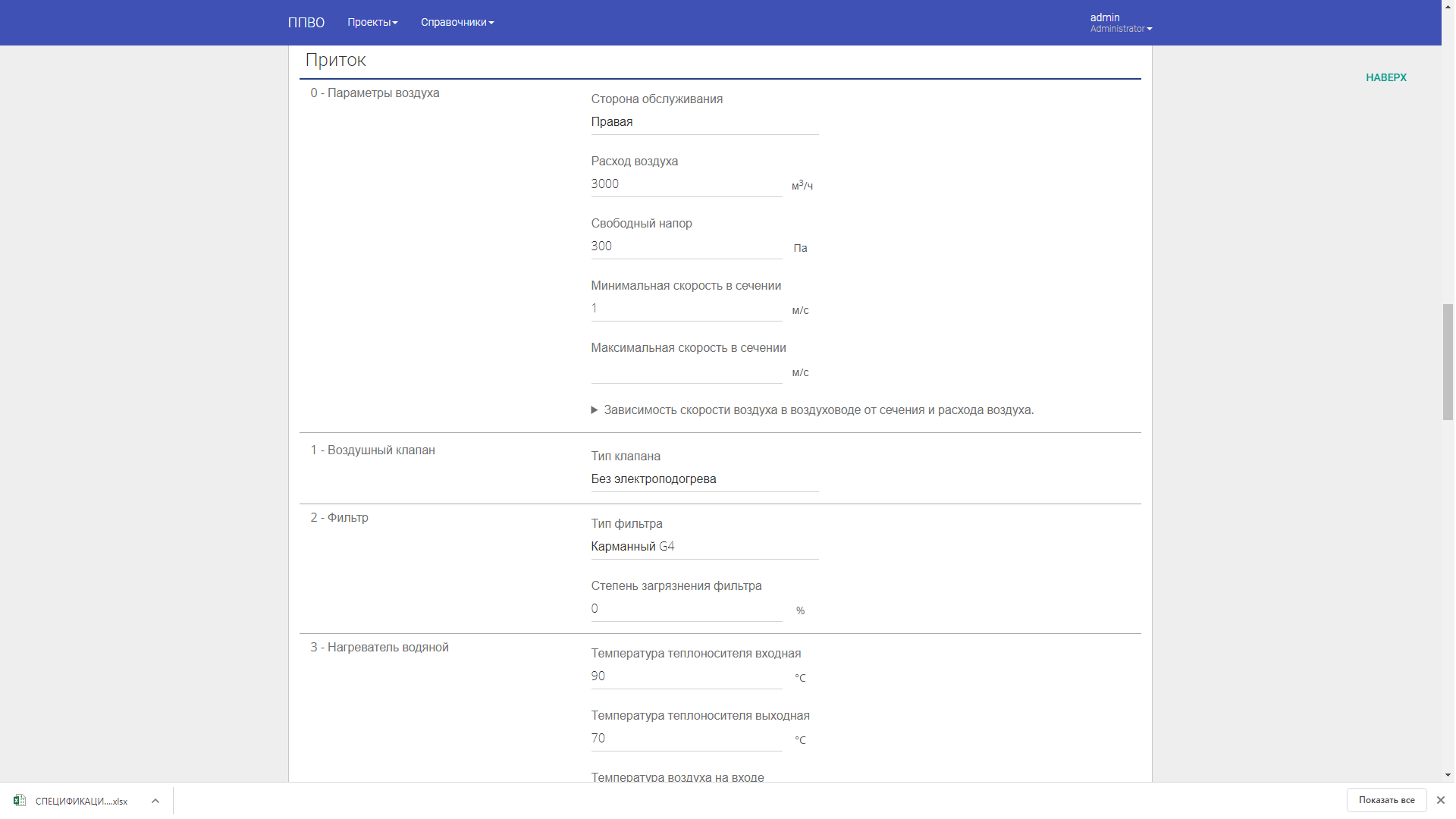

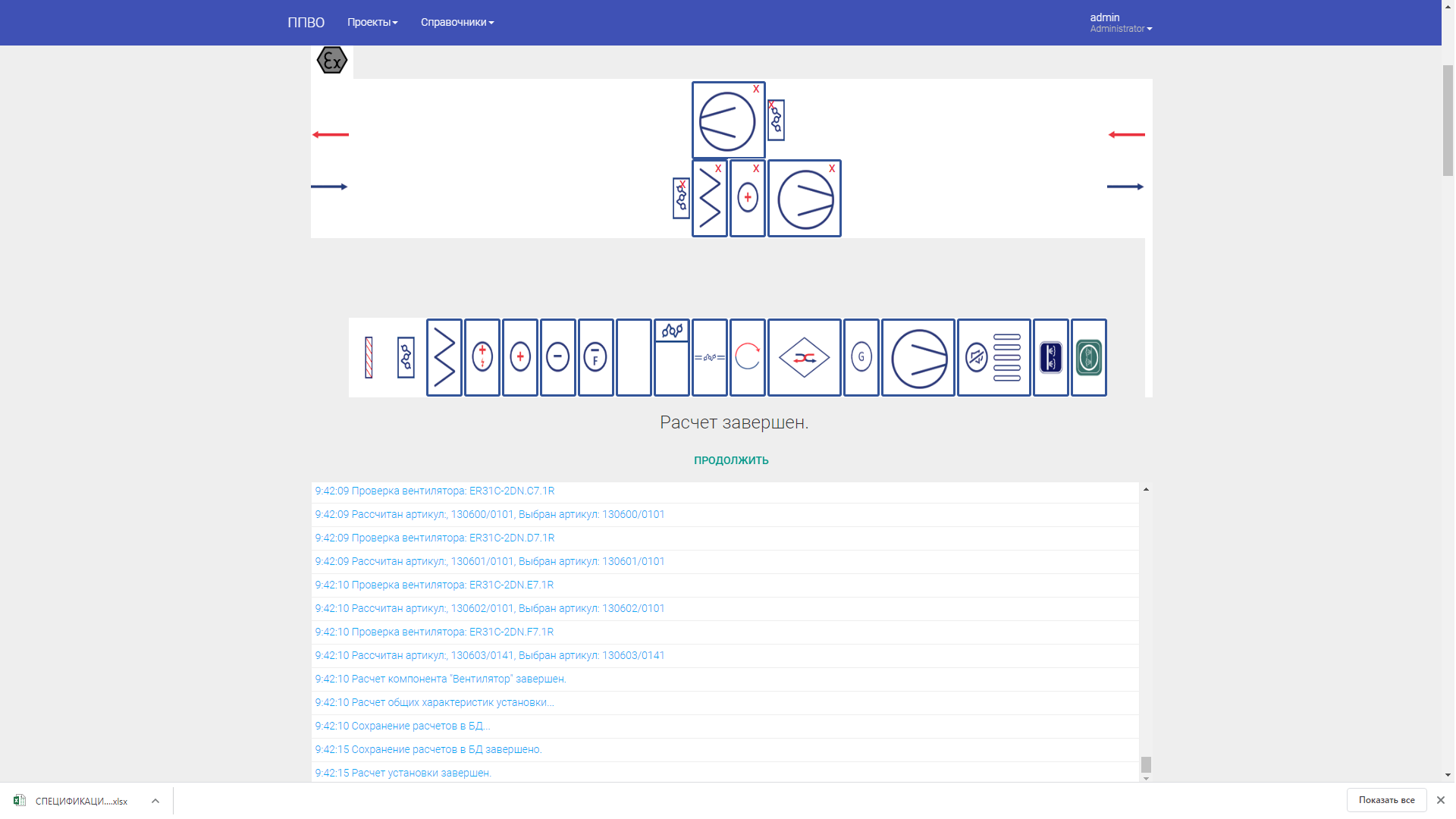

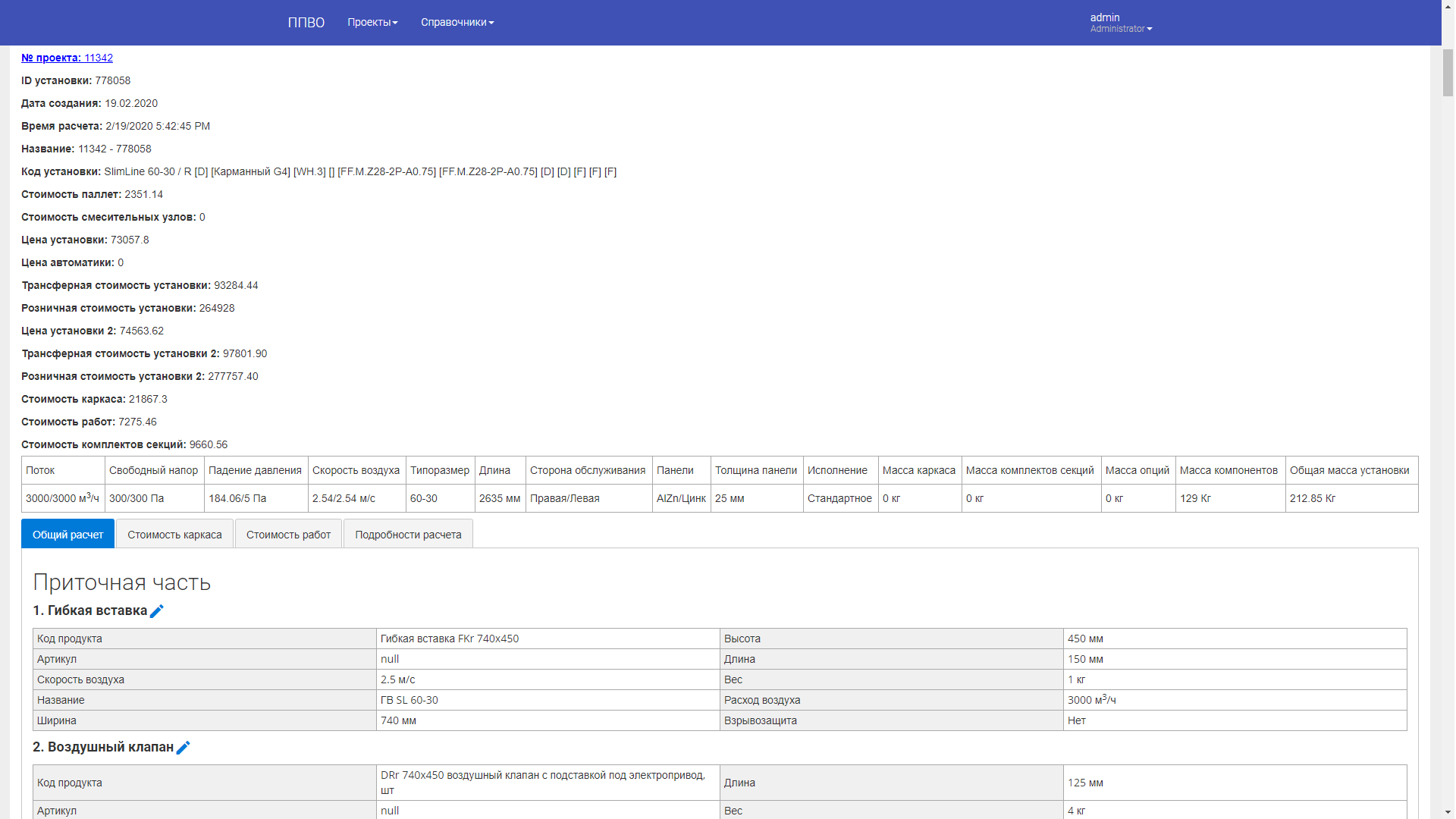

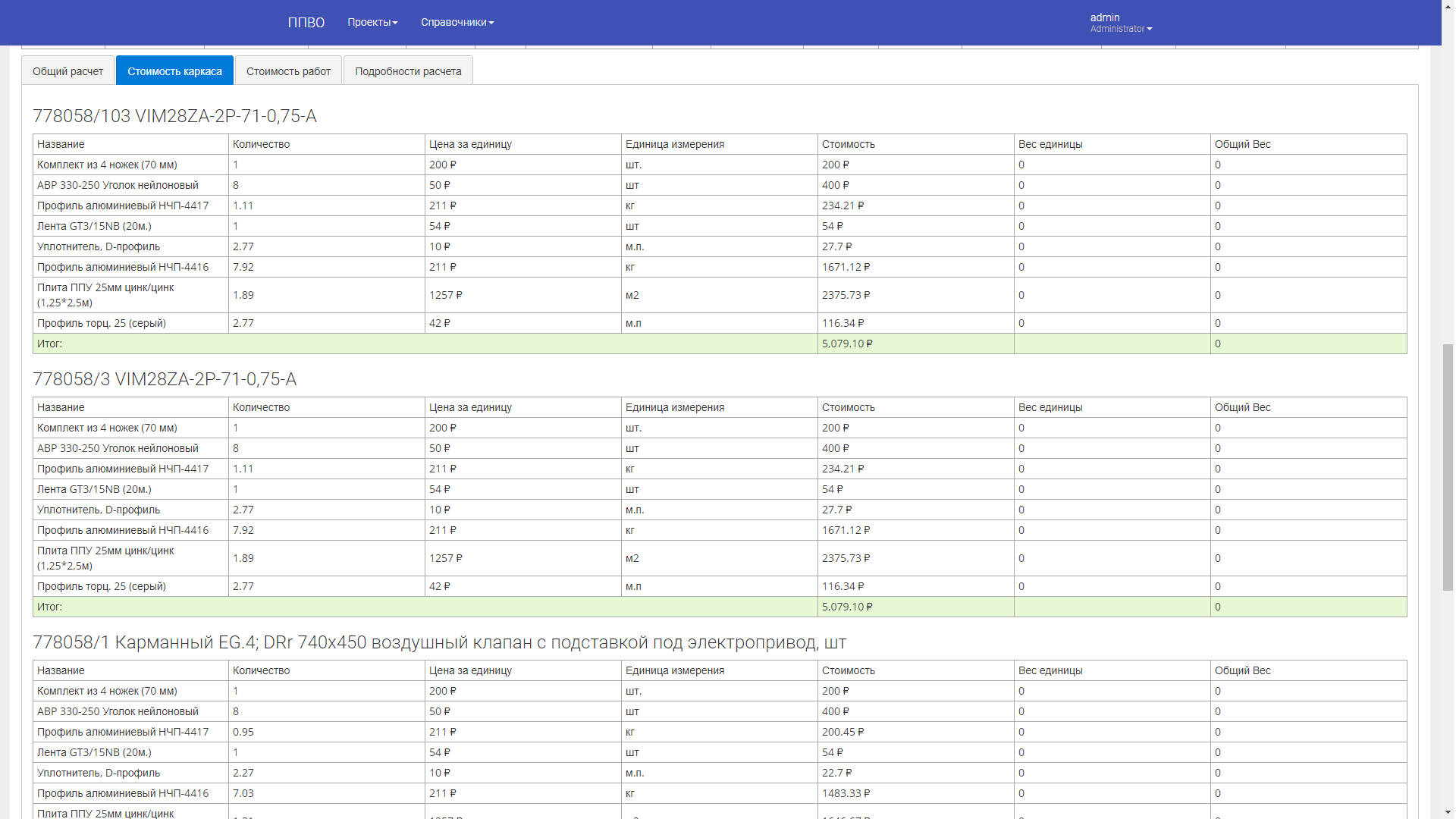

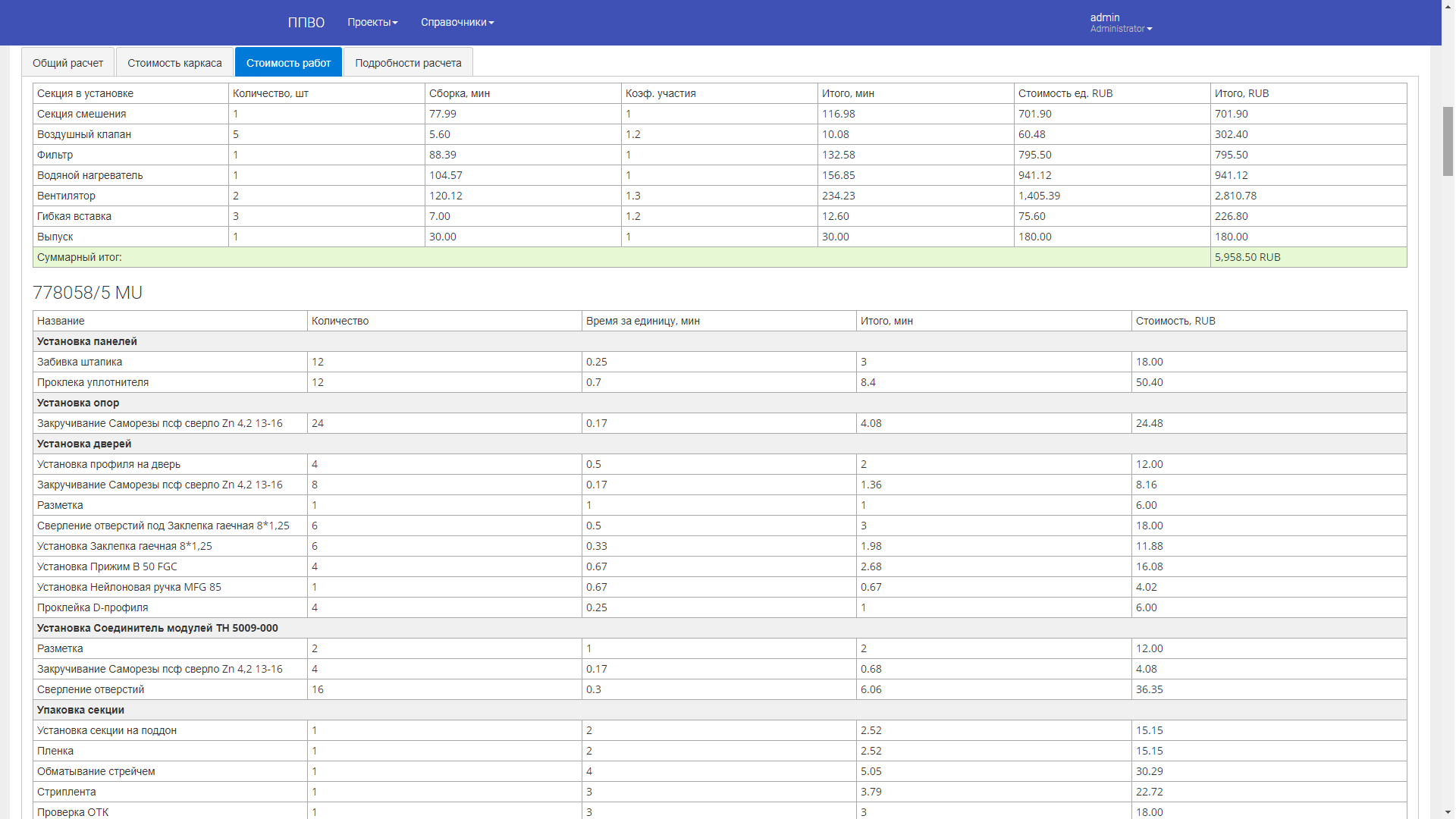

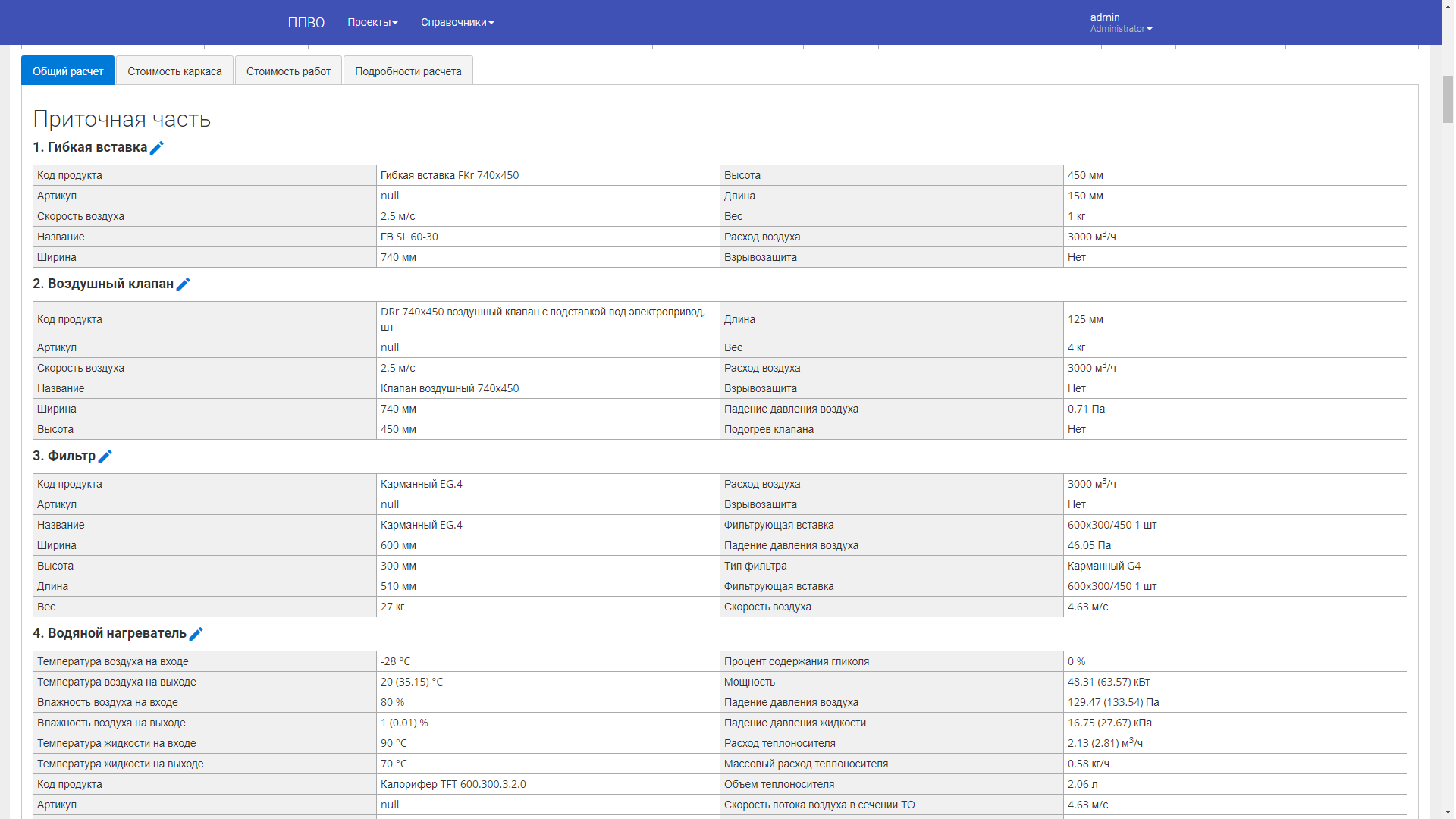

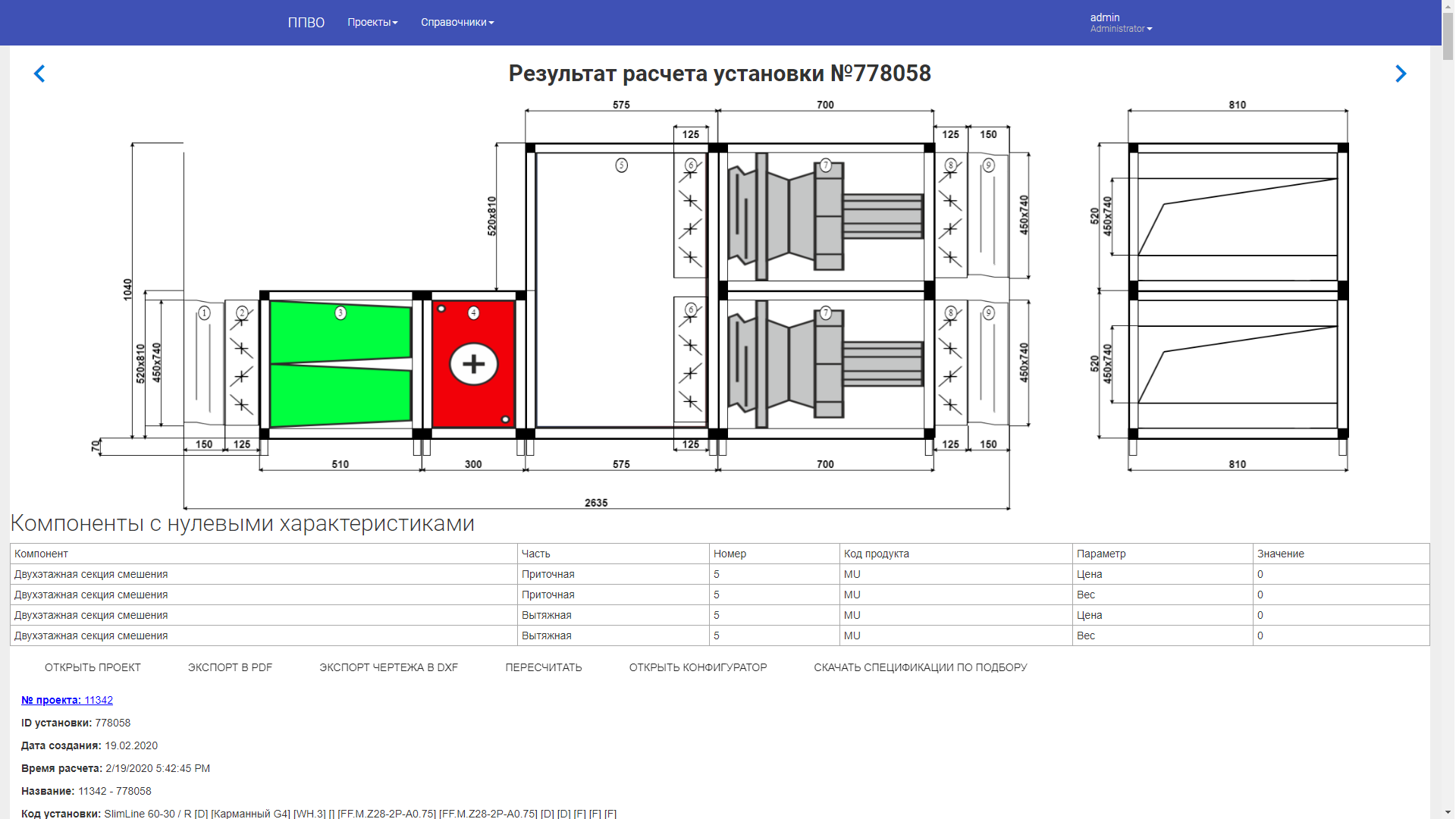

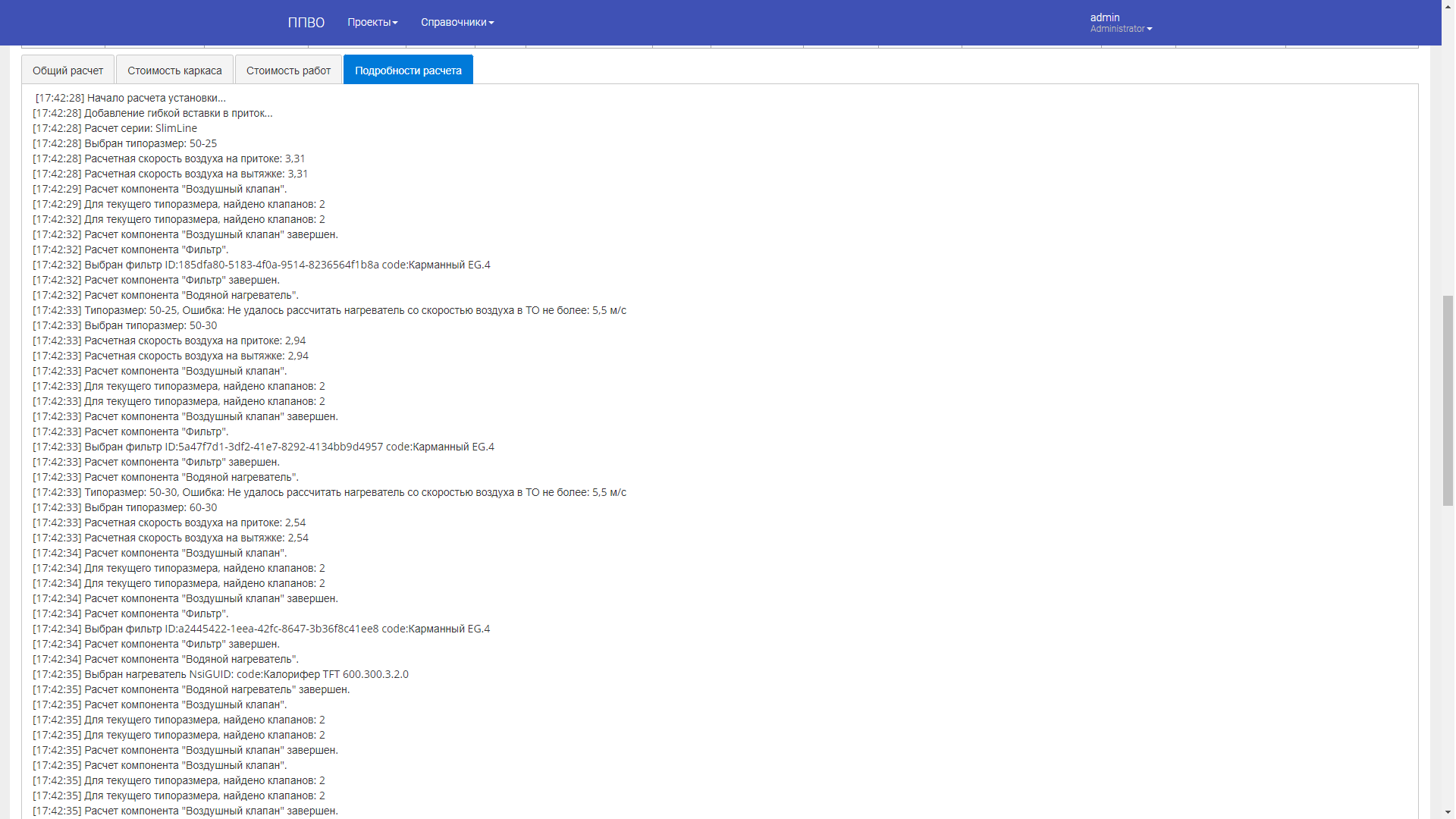

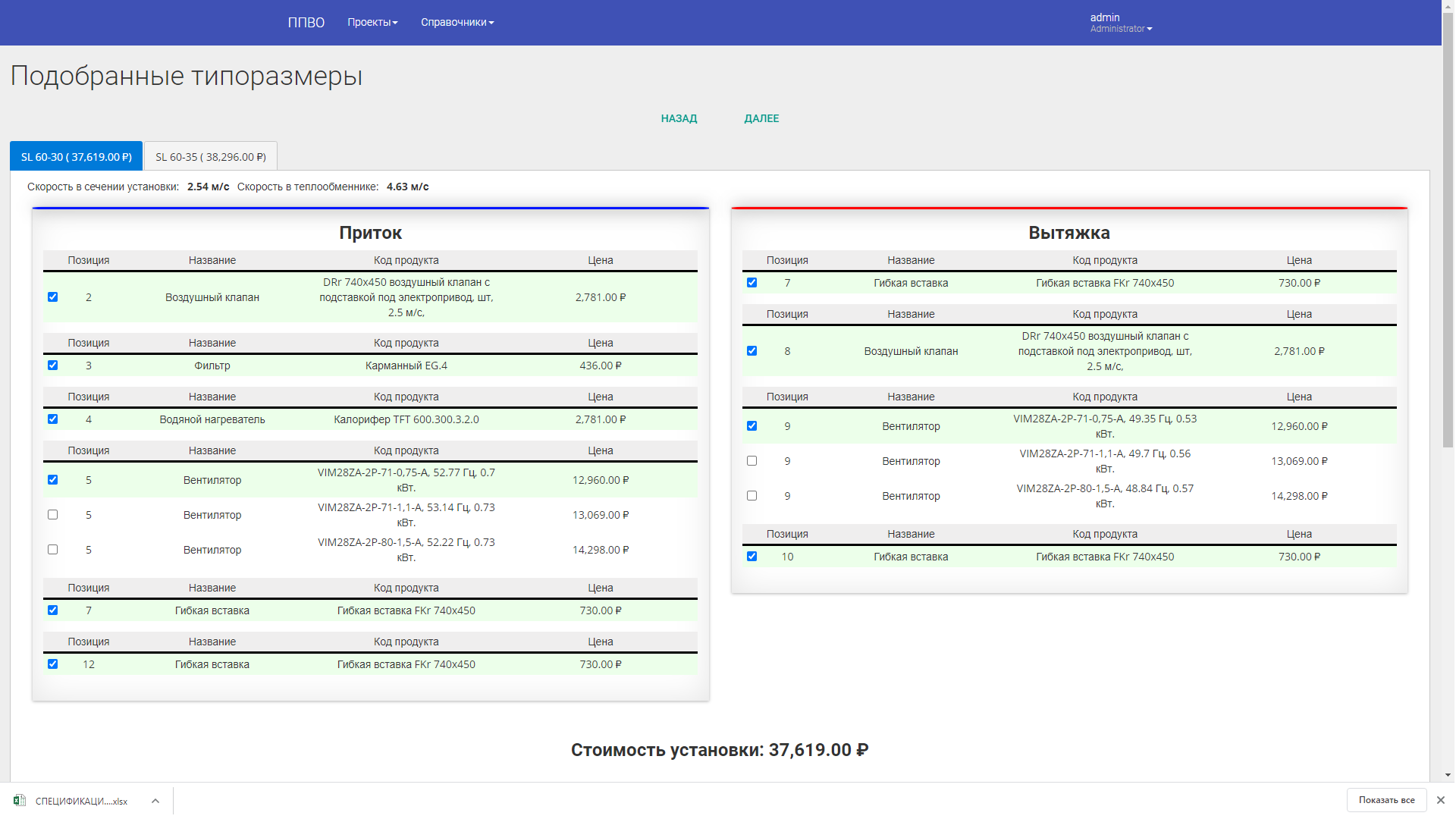

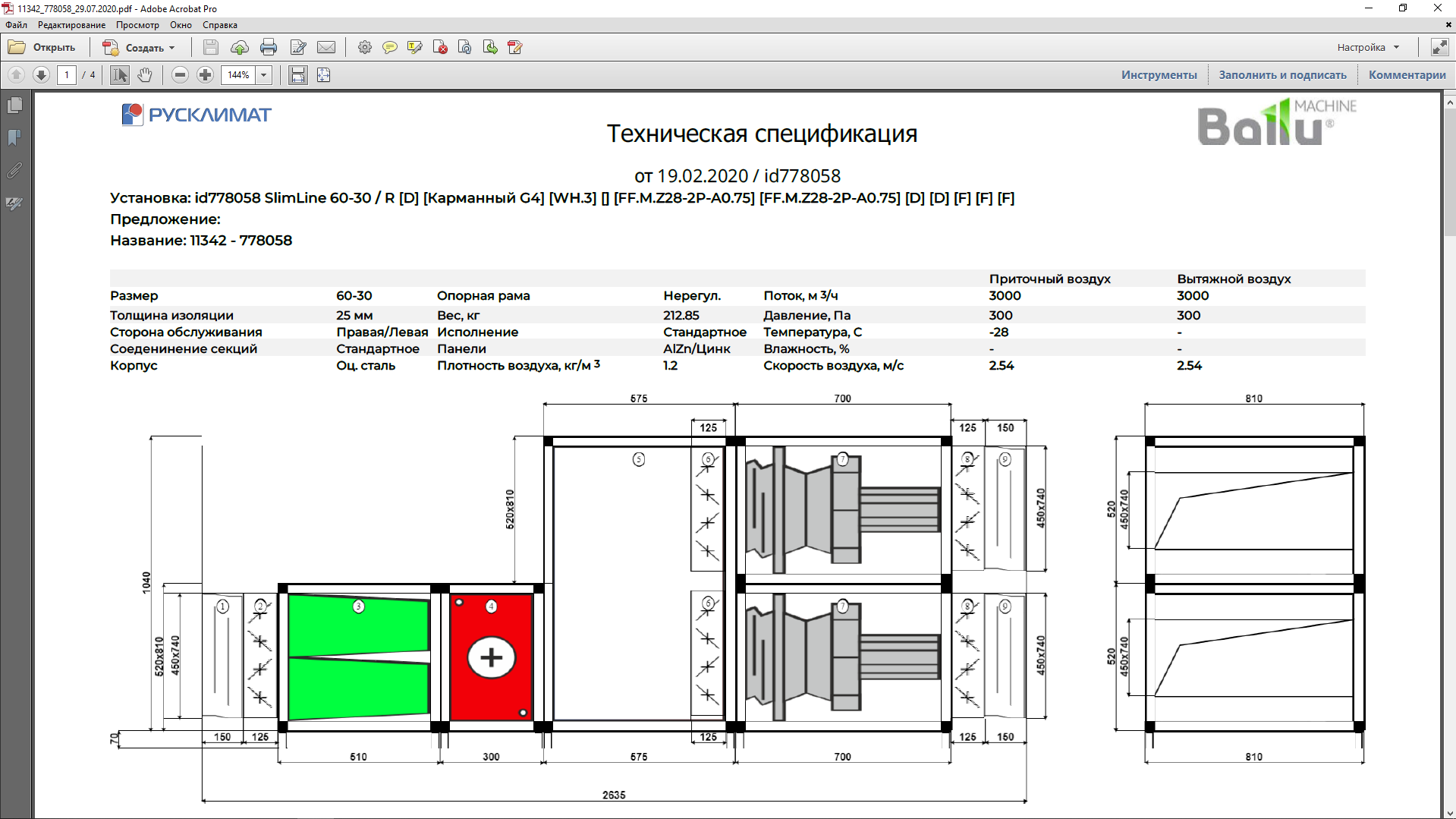

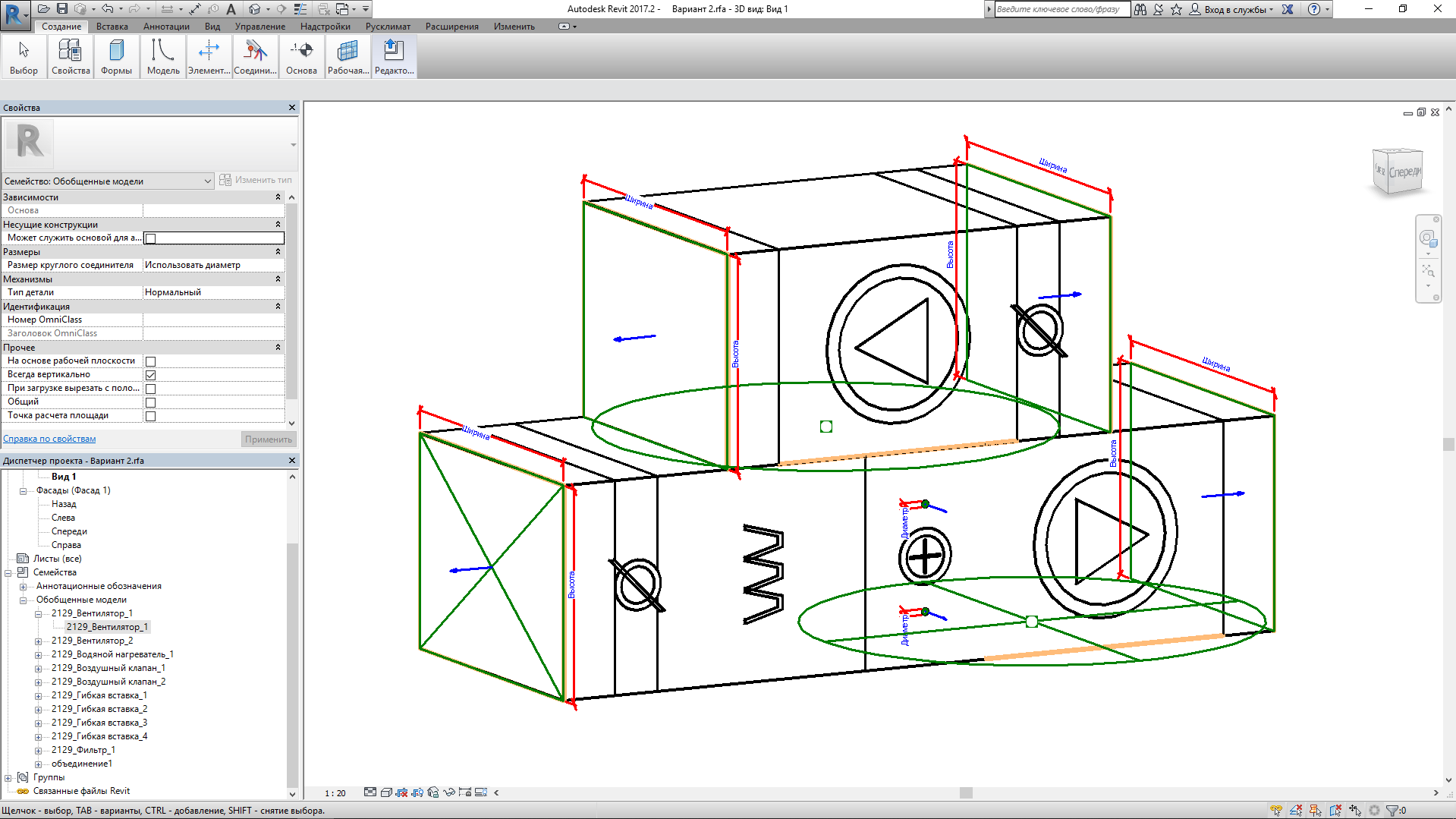

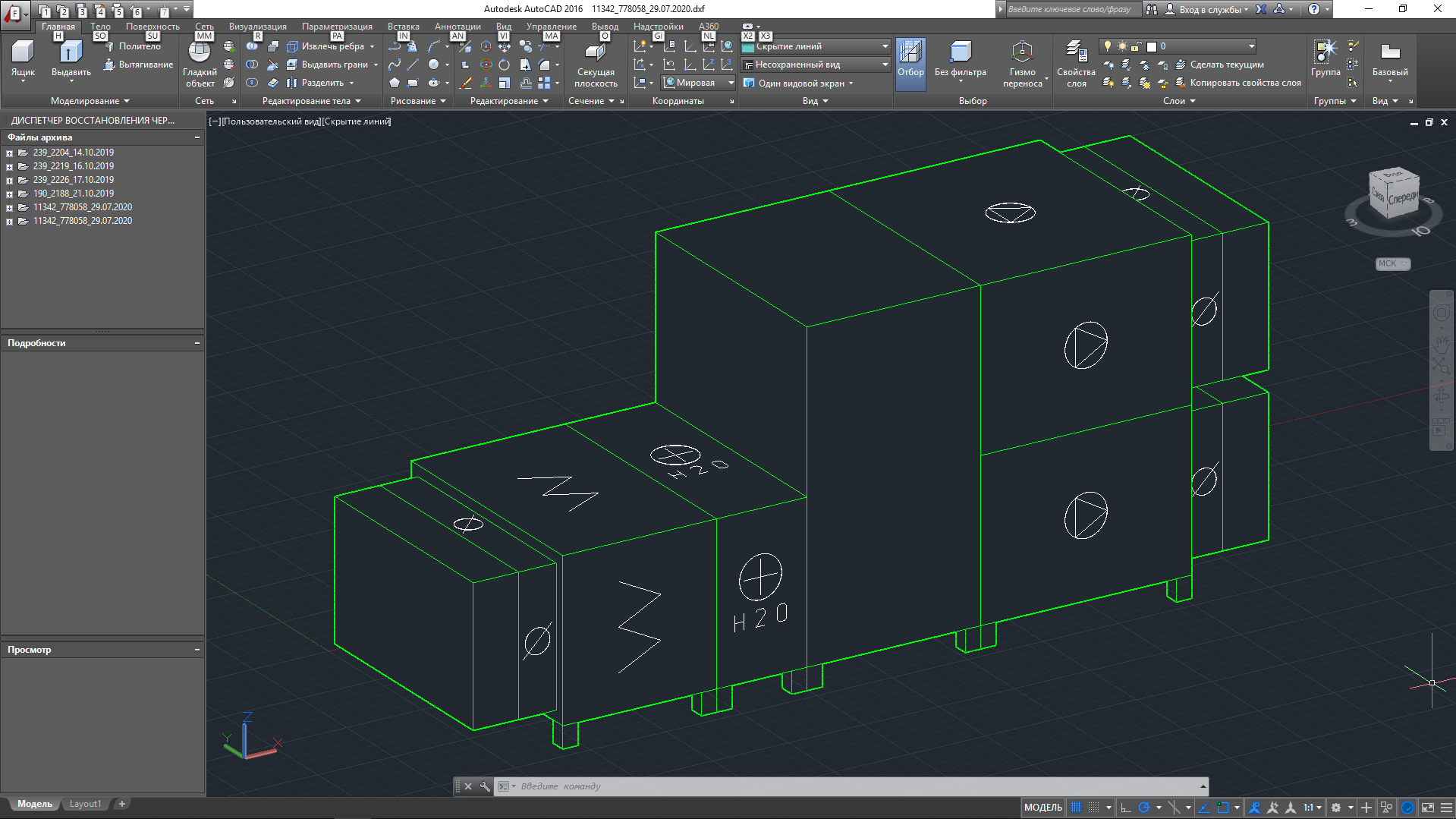

VESP includes a server and a web application for calculating operating modes and selecting the most suitable component sizes when planning for ventilation systems. The installation scheme compiled by the user in addition to the initial data on the equipment's series, the operating modes of the installation, as well as the individual components used. Now the program calculates for more than 10,000 ventilation units every month.

2002–2026

2002–2026